PowerFast II

The chipboard screw for fast and flexible applications.

- Home

- Products

- Innovations

- PowerFast II

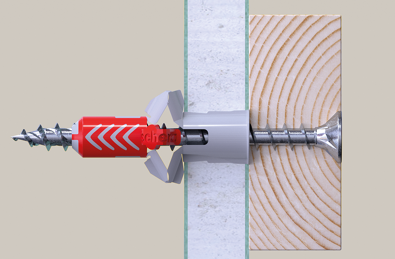

The new PowerFast II is suitable for use with fischer plugs (E.g DuoPower and UX) and recommended loads.

This offers flexible application in the plug with high load-bearing capacities.

No special screws are required.

Safe and secure with fischer plugs.