The best performance in cracked concrete for maximum tensile loads.

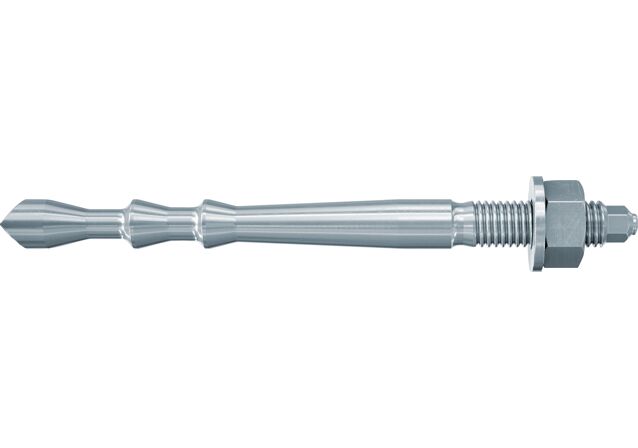

The fischer Highbond rod anchor FHB II-A L is produced from zinc-plated steel. The torque-controlled composite anchor can be processed with the Highbond special mortar FIS HB or the mortar cartridges FHB II-P and FHB II-PF HIGH SPEED. When tightening the hexagon nut, the anchor rod cones are pulled into the mortar shell, which expands against the drill hole wall. Using the fischer Highbond system FHB II means that large machines and heavy steel constructions are securely installed within internal areas.